The 122 European Study Group with Industry (ESGI) was held from 19th to 23th September 2016 at the Faculty of Mathematics of the University of Santiago de Compostela (USC), thanks to the collaboration between the Spanish Network for Mathematics & Industry (math-in) and the Technological Institute for Industrial Mathematics (ITMATI).

The 122 European Study Group with Industry (ESGI) was held from 19th to 23th September 2016 at the Faculty of Mathematics of the University of Santiago de Compostela (USC), thanks to the collaboration between the Spanish Network for Mathematics & Industry (math-in) and the Technological Institute for Industrial Mathematics (ITMATI).

Initiated in Oxford in 1968, Study Groups with Industry provide a forum for industrial scientists to work alongside academic mathematicians on problems of direct industrial relevance. They are an internationally recognized method of technology and knowledge transfer between academic mathematicians and industry.

The success of the ESGI is the unique format which has been copied around the world, in which mathematics community works on reduced groups to study problems, proposed by industry. These problems are presented from any economic sector thanks to the Mathematics’ transversally. The objective is to present the capabilities of Mathematicians and the applicability of Mathematics in a large part of the challenges and needs of the industrial, bringing small, medium and large companies a technology with great potential, with highly qualified researchers and that does not require large investments to use.

This simple format has proved its value again and again: companies from diverse industries have benefited from the insights gained through mathematical analysis of their problems, while mathematicians with diverse interests have benefited from the exciting research opportunities presented by unsolved problems with practical significance.

Therefore, collaboration between industry experts and researchers is a key to addressing technological innovation problems into a mathematical successful. The realization of ESGI contributes to the promotion of mathematics and awareness of companies to use Mathematics to improve their processes.

GOALS:

o to find solutions and insights into existing industrial problems;

o to establish lasting and productive working links between applied mathematicians and industry;

o to propose new lines of research based on business challenges;

o to reinforce the importance of mathematics in industry and to open new jobs of mathematical profile in companies; and

o to stimulate greater awareness in the wider community of the power of mathematics in providing solution paths to real-world problems.

INDUSTRIAL PROBLEMS:

In the 122 ESGI four problems were presented:

PROBLEM 1: Fleet planning of AGV´s

o Academic Coordinator: Julio González Díaz. Affiliated researcher of ITMATI, Assistant Professor at the Department of Statistics and Operations Research (USC).

o Business Coordinator: Jesús Enrique Sierra García. Academic and Scientific Relations Manager, Asti.

o Specialist: Juan José Salazar González. Professor of Statistics and Operations Research, University of La Laguna (Tenerife).

o Description: The AGVs (automatic guided vehicles) are automatic vehicles for transporting loads in production environments. AGVs in intralogistics systems are not used individually, but fleets of AGVs. The plant system sends commands indicating the source station and the destination station to a monitoring system fleet (SCF). The SCF assigns each order to an AGV within the fleet of AGVs. Currently, this assignment is not optimal and occurs locks and waiting periods that limit the productivity.

o Further information: 122 ESGI (problem 1).

PROBLEM 2: Big Data Information processing obtained from inspection of quality management.

o Academic Coordinator: Rosa Crujeiras, Affiliated researcher of ITMATI, Associate Professor at the Department of Statistics and Operations Research (USC).

o Business Coordinator: Hugo Caridad Cordeiro, CEO iAuditoria.

o Description: Companies must address compliance relating to food safety, prevention of occupational hazards and environmental quality legal and contractual requirements. To do so, within the control and monitoring methodologies is conducting inspections and / or audits in order to verify compliance with them. Generally, these inspections and audits are collected as mere compliance with the requirements without companies to allocate time and resources to analyzing them. iAuditoria is an ICT tool that solves this problem and that in any case wants to go further and deal with predictive models generated from the results of such inspections and audits the possibility of facing situation of food crises, accidents or environmental disasters.

o Further information: 122 ESGI (problem 2).

PROBLEM 3: Efficient Simulation Method for Current and Power distribution in Electrical Furnaces

o Academic Coordinator: Mª Pilar Salgado Rodríguez. Affiliated researcher of ITMATI. Associate Professor at the Department of Applied Mathematics (USC).

o Business Coordinator: Svenn Anton Halvorsen. Senior Researcher of Applied Mathematics. Teknova AS.

o Description: Mathematical modelling has successfully been applied for various aspects of metallurgical processes. Nevertheless, due to all complexities in the processes, the design and operation of smelting furnaces are still to a large degree empirically based, and several process variations are not properly understood. One identified knowledge gap is an accurate understanding of the effects of 3-phase alternating current, including how the associated power distribution governs the chemical reactions and temperature distribution. An efficient method for computing 3-phase current paths and power distribution is a required step to close this knowledge gap. Previous simulations within metallurgy have often applied direct current (DC), to study large, 3-phase, smelting furnaces. Such DC simulations are valid for “only one instant of time” and it is not straightforward to interpret the results for real furnaces. We have shown that an approximate harmonic solution for 3-phase alternating currents (AC) can be described as a superposition of three DC solutions, taking the phase shift between the three electrodes into account. This simplified AC-model will be presented at the IFAC MMM symposium, Vienna, 31 August – 2 September 2016.The ESGI shall focus on comparing the simplified model with full AC 3-phase simulations including electromagnetic induction. The simplified AC approximation is valid for small furnaces. We now want to clarify how well it works for large ones.

o Further information: 122 ESGI (problem 3).

PROBLEM 4: Creation of an “Oracle” to support facilities management

o Academic Coordinator: Javier Roca Pardiñas Affiliated researcher of ITMATI. Associate Professor of Statistics and Operations Research (University of Vigo).

o Business Coordinator: Pedro Perez Gabriel, Managing Director of Eco-management Technology S.L. (EcoMT)

o Description: EcoMT is an ICT company dedicated to implementing solutions for monitoring and remote facilities management based on expert system technology and applied to plants responds to a concept of “multisite” with particular characteristics: relative simplicity, high number of similar facilities and limited financial and technical resources for operation and maintenance. We have developed a platform for remote management and monitoring (OTEA) which aims to make a comprehensive management of the different facilities, its latest developments place it in the field of expert systems, with the ultimate goal to be able to make intelligent decisions to manage the facilities which controls (air conditioning, lighting, water treatment systems, …) without human intervention and low cost of implementation. EcoMT is an ICT company dedicated to implementing solutions for monitoring and remote facilities management based on expert system technology and applied to plants responds to a concept of “multisite” with particular characteristics: relative simplicity, high number of similar facilities and limited financial and technical resources for operation and maintenance. We have developed a platform for remote management and monitoring (OTEA) which aims to make a comprehensive management of the different facilities, its latest developments place it in the field of expert systems, with the ultimate goal to be able to make intelligent decisions to manage the facilities which controls (air conditioning, lighting, water treatment systems, …) without human intervention and low cost of implementation. Today, there is ample historical data sets (more than 5 years, more than 1800 installations each with a number of variables treated between 100 and 300) of the behaviour of different facilities (air conditioning and lighting) in multiple geographic locations and in many cases they could respond to patterns (hidden or view).Systems that are tele-management, especially air conditioning systems are designed with deterministic rules with the aim of achieving certain conditions of thermal comfort for users, however the actual performance of facilities depends on variables with a strong probabilistic nature such as be: external temperature conditions, the occupation of the premises, maintenance interventions …What is sought is the creation of an “oracle” that can give answers and generate rules of operation for the user issues advanced no demands and consultation of the expert is not necessary. To do this, and some steps (2014/2015) were given using neural networks, Bayesian networks, regression … obtaining predictive algorithms that generate risk maps that provide information about which facilities have a higher risk that comfort conditions are not met in certain circumstances and operating environment. The initial idea we have is that the wizard (oracle), fed and trained with the historical database, incorporating various modules (algorithms) that allow you to master specific topics within that area. In the future the “oracle” will evolve into “genius” or “sovereign” so that no human intervention was required to manage the facilities on which applies. In this new phase it is intended to at least choose to offer the best performance algorithms to implement in the oracle according to the type of data that we have and facilities for which they apply.

o Further information: 122 ESGI (problem 4).

PARTICIPATING ENTITIES AND ENTERPRISES:

PARTICIPATING ENTITIES AND ENTERPRISES:

o Asti

o iAuditoria

o Teknova

o EcoMT

SCIENTIFIC COMMITTEE

o Cao Abad, Ricardo. Professor of Statistics and Operations Research. University of A Coruña. Affiliated researcher of ITMATI.

o Parés Madroñal, Carlos. Professor of Applied Mathematics at the University of Malaga and Vice-President of the Spanish Network for Mathematics and Industry (math-in).

o Roca Pardiñas, Javier. Associate Professor of Statistics and Operations Research. University of Vigo. Affiliated researcher of ITMATI.

o Rubio García, Julio. Professor of Computer Science and Artificial Intelligence. University of La Rioja. Member of math-in.

o Salgado Rodríguez, Mª Pilar. Associate Professor of Applied Mathematics. University of Santiago de Compostela. Affiliated researcher of ITMATI.

ORGANIZING COMMITTEE

o Castro Novo, Adriana. Technology transfer and innovation manager. ITMATI.

o Gayoso Taboada, Rubén. Manager. ITMATI.

o Prieto Aneiros, Andrés. Associate Professor in the Department of Mathematics of the Faculty of Computer Science. University of A Coruña. Affiliated researcher of ITMATI.

o Sampayo Fernández, María Fe. Translator or technology. Math-in.

CALL FOR COMPANIES

This year, for the first time, an open call for companies who want to present an industrial problem in 122 ESGI were carried out.

Further information: http://www.math-in.net/122esgi/en/call

FURTHER INFORMATION AND SCHEDULE: http://www.math-in.net/122esgi/

REPORT AND PHOTOGRAPHS: http://www.itmati.com/en/122-esgi-week-free-mathematics-solve-industrial-problems

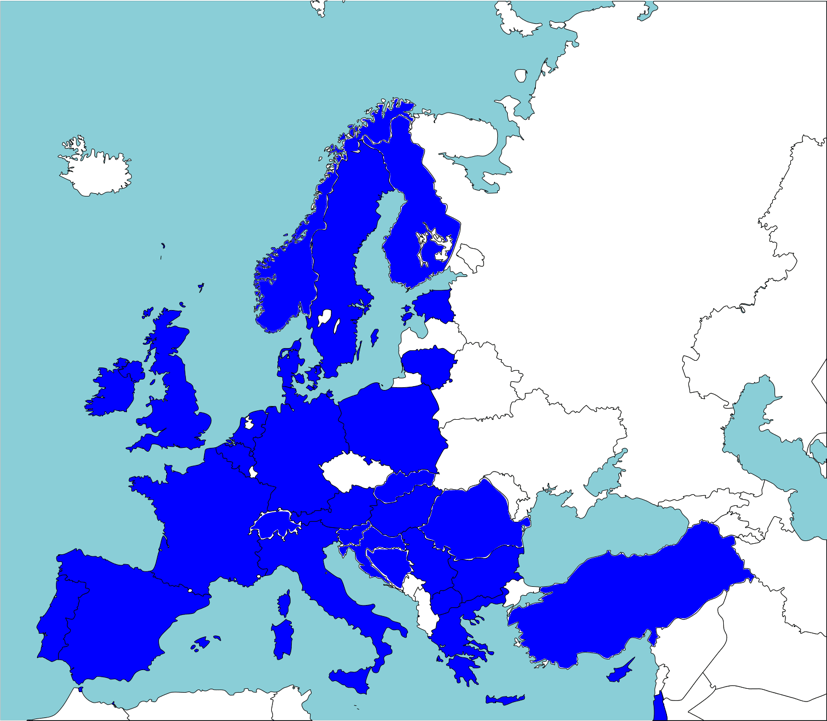

w grown to include 31 countries.

w grown to include 31 countries.

This MW, supported by

This MW, supported by  On the 12th-16th September 2016 in the University of Glasgow,

On the 12th-16th September 2016 in the University of Glasgow,

PARTICIPATING ENTITIES AND ENTERPRISES:

PARTICIPATING ENTITIES AND ENTERPRISES: